Sanitary: Life Science/Food & Beverage

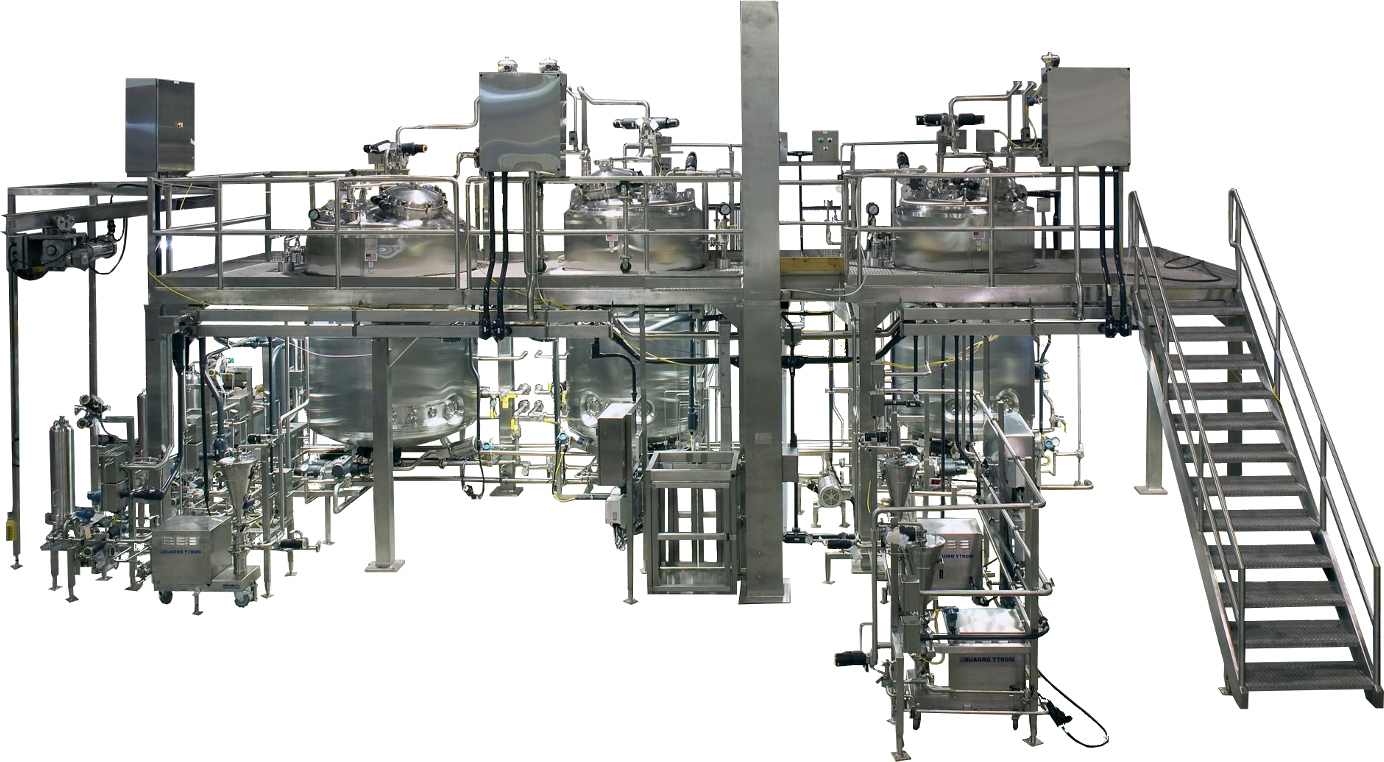

Tanks & Tank Accessories:

- Storage, Process, & Utility Tanks

- Top & Side-mounted Agitators

- Bottom Mag-drive Mixers

- Batch & Inline High-Shear Mixers & Powder-Liquid Stations

- Bottom Outlet Valves

- Sample Valves

- Custom Single-Use Assemblies (Tubing, Manifolds, Sampling Assemblies)

- Spray Balls

Heat Exchangers:

- Sanitary Shell & Tube Heat Exchangers, including Corrugated & Twisted Tube

- Plate Heat Exchangers (Gasketed, Semi-Welded, Fusion-Bonded, Brazed)

- Spiral & COMPABLOC All-welded

- Platular®

- Multi-tube, Hairpin, Coil, Double Wall

- Bulk Solids

- Flue Gas Condensers

- Pillow Plate Elements & Bundles

- Electric heaters, heating elements, & heating accessories

Piping:

- Stainless Steel

- Reactive Metal

- Glass-lined

- PTFE-lined

- Fiberglass Pipe & Fittings

Centrifuges:

- Batch Vertical Scraper

- Batch Horizontal Scraper

Filter Housings & Filtration Systems:

- Sanitary Cartridge & Depth Filter Housings

- Rotary Drum Vacuum Filters

- Horizontal Vacuum Belt Filters

- Fully Automated Filter Presses

- Self-Cleaning Pressure Leaf Systems

- Candle Pressure Filter Systems

- Continuous Rotary Pressure Filters

- Nutsche Filters, Nutsche Filter-Dryers

Vacuum Pumps:

- Small Lab/Pilot Plant Dry & Oil-sealed

- Dry Claw & Scroll

- Oil-sealed

- Mechanical Boosters

- Vapor Boosters

- Steam Jets

Dryers:

- Nutsche Filters & Filter-Dryers

- Vacuum Dryers

- Airstream Dryers, Coolers, & Calciners (Tube Bundle, Spray, Ring, and Flash)

Corrosion-resistant equipment:

- Graphite & Exotic Metal Process Equipment (Heat Exchangers, Pumps, Systems, Column Internals)

- PTFE-lined Columns & Vessels

- PTFE-lined Pipe & Fittings

- Glass-Lined Process Equipment (Tanks/Columns, Pipe, Heat Exchangers, etc.)

- Fiberglass Scrubbers, Ventilation Equipment, Structural supplies, Stacks & Chimney liners;

- On-site Fiberglass Manufacturing Services

Miscellaneous:

- Transfer Panels

- Valve Clusters

- Control Panels

- Hold (Retention) Tube Assemblies

- Custom-designed manifolds, spool pieces, & piping configurations

- Stainless Steel Platform Assemblies

- Custom/machined stainless steel fabrications

- Clean-Out-of-Place (COP) Baths

Process:

Upstream:

- Bulk Pasteurization

- High Temperature-Short Time (HTST)

- Media/Buffer Prep

- Formulation

- Buffer Stock Blending (BSB)

- Seed & Production Fermentors & Bioreactors

- Clean-In-Place Skids

Downstream:

- Large Tank/Platform Systems/Harvest Hold

- Centrifuge

- Homogenizer

- Filtration – Ultrafiltration-Diafiltration (UFDF), Microfiltration, Depth

- Chromatography

- Inactivation

Utility Skids:

- Clean-In-Place (CIP)

- Purified Water & WFI Storage & Distribution

- Purified Water & WFI Generation

- Bio-Kill & Waste pH Neutralization

- Heat Transfer

Fill/Finish:

- Formulation & Sterile Storage

- Custom equipment for Powder Transfers, Bulk Handling, Dosing, Dispensing, Blending, Sampling, Milling, & Micronizing, Aseptic Fill Lines, Fill-finish Solutions Inside an Isolator

- Isolators for Sterile, HPAPI, Down flow Booths, Mobile Clean Rooms, Radiopharmaceuticals

- Safe handling of toxic & corrosive liquids

- Powder Handling Accessories: Suction Hopper, Fluidization Cone to prevent bridging & rat-holing, Bellows, Security Filter, Safe Change Filter, Bypass, Venting Filter, Vacuum Pump, Mobile Trolley, Lump Breaker Suction Lance, Lump Breaker - Pharma Design, SafeSeal Closing System, Retractable Spray Ball, Rotary Valve, DosiValve® (simple and cost-effective solution for the dosing of powders & granules)

- PTS Batchmixer® Powder Mixer/Blender

Field Services:

- Services related to Stainless Steel: Stainless Steel Passivation; Pickling/Chemical Cleaning; Electro-polishing; Mechanical polishing; Vessel or Tank Repair; Vessel Refurbishment

- Services related to Fiberglass: Plant Site Surveys, Field Dimensions, Layout and Design, Materials Engineering, Stress Analysis and FEA, Pipe and Ductwork Support, Installation and Modification, Field Inspection and Analysis, Maintenance and Repair, Site Supervision and Training, ASME and FRPI Stamping, Field Hydro Testing, Acoustic Emissions (AE) Testing, Turnkey Services

Process Industrial: Chemical Process/Pulp & Paper

Tanks & Tank Accessories:

- Stainless Steel: Tanks & Reactors; Storage, Process, & Utility

- Reactive Metal: Pressure vessels, columns, reactors, heat exchangers, & piping from corrosion-resistant alloys (CRA), including Titanium, Tantalum, Zirconium, Hastelloy®, Niobium, Monel, Inconel, High Nickel Alloys, Duplex Stainless Steel, Super Stainless Steel, and Lean Duplex Stainless Steel.

- Glass-lined: Reactors, Agitators, & Receivers/Tanks/Phase Separators

- LICUFLON PTFE lined steel columns

- Graphite: Columns & Column Internals

- Fiberglass Tanks & Vessels, Stacks & Chimney Liners; On-Site Fiberglass Manufacturing Services

- Agitators (Top & Side entry)

- High-shear mixers

Heat Exchangers:

Plate Technology:

- Gasketed Plate

- Brazed Plate

- Semi-Welded Plate

- All-welded Plate

- All-welded Spiral

- All-welded COMPABLOC® Cross-Flow

- All-welded Platular®

- Plate Evaporators

- Plate Condensers

- Energy Recovery & Heat Integration

Tubular Technology:

- Carbon/Stainless Steel: Shell & Tube

- Reactive Metal: TEMA-type heat exchangers & condensers made of corrosion-resistant alloys (CRAs), including Titanium, Tantalum, Zirconium, Hastelloy®, High-Nickel Alloys, Duplex, and Super Duplex Stainless Steels.

- Glass-lined: Condensers and Shell & Tube Heat Exchangers

- Twisted-tube

- Hairpin

- Tank Line Heaters/Finned Tubes

- Falling Film Evaporators

Electric heaters, heating elements, & heating accessories

Piping:

- Stainless Steel

- Reactive Metal

- Glass-lined

- PTFE-lined

- Fiberglass Pipe & Fittings

Centrifuges:

- Continuous Pusher

- Batch Vertical Scraper

- Batch Horizontal Scraper

Filter Housings & Filtration Systems:

- Industrial Filtration Systems

- Rotary Drum Vacuum Filters

- Horizontal Vacuum Belt Filters

- Filter Presses

- Self-Cleaning Pressure Leaf Systems

- Candle Pressure Filter Systems

- Continuous Rotary Pressure Filters

- Sand Filters

- Deep Media Upflow Filter

- Fine Oil & Suspended Solids Nutshell Filters

- Nutsche Filters, Nutsche Filter-Dryers

- Single & Multi-layer (sintered) Metal Filter Mesh Elements for candle filters, Bag Filters, Disc Filters, Melt Filters, Polymer Candle Filters, Spinning Nozzle Filters, Nutsche filters & filter-dryers, Vacuum Dryers, & Fluid Bed Dryers

Separation & Extraction Systems:

- Ion Exchange Systems

- Liquid-liquid Extraction Systems

- Batch Solid-liquid Solvent Extraction Systems for Vegetable Materials

Vacuum Pumps:

- Small Lab/Pilot Plant Dry & Oil-sealed

- Dry Oil-sealed

- Mechanical Boosters

- Vapor Boosters

- Steam Jets

Dryers:

- Nutsche Filter-Dryers

- Vacuum Dryers

- Air stream Dryers, Coolers, & Calciners (Flash, Ring, Fluidized Bed, Rotary Drum, & Column)

Corrosion-resistant equipment:

- Graphite & Exotic Metal Process Equipment (Heat Exchangers, Pumps, Systems, Column Internals)

- PTFE-lined Columns & Vessels;

- PTFE-lined Pipe & Fittings

- Glass-Lined Process Equipment (Tanks/Columns, Pipe, Heat Exchangers, etc.)

- Fiberglass Scrubbers, Ventilation Equipment, Structural supplies, Stacks & Chimney Liners; On-Site Fiberglass Manufacturing Services

Miscellaneous:

- Transfer Panels

- Valve Clusters

- Control Panels

- Hold (Retention) Tube Assemblies

- Custom-designed manifolds, spool pieces, & piping configurations

- Stainless Steel Platform Assemblies

- Custom/machined stainless steel fabrications

- Clean-Out-of-Place (COP) Baths

Process:

- Reactor/Tank Skids

- Polymer Reaction Skids

- Process Vacuum Skids

- Filtration Skids: Microfiltration, Ultrafiltration, Nanofiltration, RO-EDI, Pressure Leaf/Candle/Multi-media Skids, Rotary Drum Vacuum Filter Skids, Horizontal Vacuum Filter Skids, Industrial Filtration Skids

- Mass Transfer: Fermentation, Rectification & Reactive Distillation, Solvent Recovery, Membrane & Pervaporation Technology, Liquid-liquid Extraction, Film Evaporation

Utility Skids:

- Heat Exchanger & Temperature Control

- Electrically-fired Hot Oil Skids

- Gas-fired Hot Oil Skids

- Clean-In-Place (CIP)

- Water Generation & Treatment (Purified Water Generation, Storage & Distribution, pH) Neutralization, Boiler Feed, Bio-Kill

- Ion Exchange, Multi-Media, and Sand Filtration

- Wet Scrubber Skids

- Reactor/Tank Platforms, Solution & Slurry Formulation, Fermentation Trains

- Distillation/Absorption/Stripping

- Rectification & Reaction Technology

- Solvent Recovery

- Reactive Distillation (combining distillation & chemical reaction into one step)

- Membranes, Pervaporation & Vapor Permeation

- Liquid-liquid Extraction

- Film Evaporation

- Special Condensers

- Freeze Concentration

- Fractional Crystallization

- Suspension Crystallization

- Combination Distillation/Crystallization Plants

- Polymer Production Technology

- Wastewater Stripper Plants

- Integrated Industrial Wastewater Plants

- Custom equipment for powder Transferring, Filling, Emptying, Dosing, Blending, Sampling, Milling, & Micronizing

- Containment Isolators

- Safe handling of toxic & corrosive liquids

- Powder Handling Accessories: Suction Hopper, Bellows, Security Filter, Safe Change Filter, Bypass, Venting Filter, Vacuum Pump, Mobile Trolley, Lump Breaker Suction Lance, Lump Breaker - Pharma Design, SafeSeal Closing System, Retractable Spray Ball, Rotary Valve

- Batch Powder Mixer

- Services related to Stainless Steel: Stainless Steel Passivation; Pickling/Chemical Cleaning; Electro-polishing; Mechanical polishing; Vessel or Tank Repair; Vessel Refurbishment

- Services related to Fiberglass: Plant Site Surveys, Field Dimensions, Layout and Design, Materials Engineering, Stress Analysis and FEA, Pipe and Ductwork Support, Installation and Modification, Field Inspection and Analysis, Maintenance and Repair, Site Supervision and Training, ASME and FRPI Stamping, Field Hydro Testing, Acoustic Emissions (AE) Testing, Turnkey Services